Specialty Solutions For Over 25 Years

What We Do

For 25 years we’ve been delivering unrivaled customer service. Decade after decade, our loyal customers have depended on us for high quality, innovative engineered solutions. Thorough on-site evaluations allow us to do what we’re best at – designing specialty cable solutions. You can be confident that SWC’s experienced professionals will work with you to solve your technical challenges, engineer and quality test the cable. With our in house cable manufacturing, assembly, molding and machining capabilities we can meet demanding timelines.

Our History

Since designing cables in his garage to working in large corporations, Bal has spent the last 25 years dedicated to resolving complex cable issues. The quality is not only reflected in his own work, but also in the calibre of the team of hand-picked, highly trained experts.

Our Mission

Founder's Vision

Customer Experience

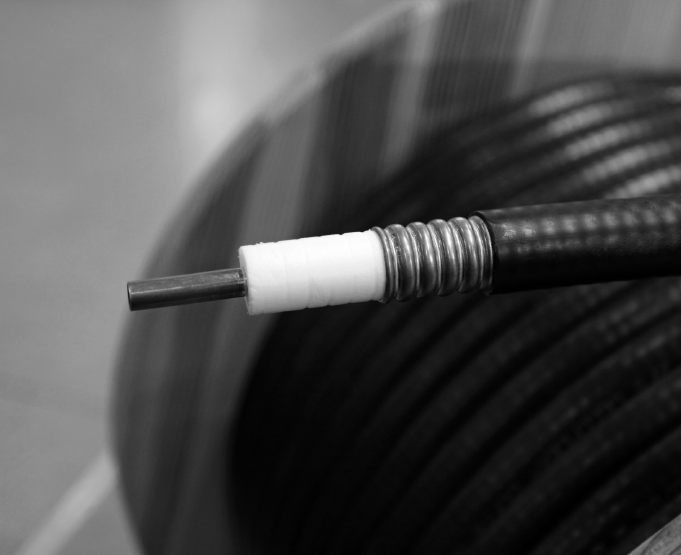

High pressure agriculture solution.

An agriculture client needed a cable that would help measure temperature at various heights in a grain bin. The client had been unsuccessful in combining a sample cable with an aircraft cable in a reliable and efficient way, and left their cables with SWC. Bal created a new design that combined the aircraft cable (built for high pressure and extreme tension) with the main cable, also using food-safe plastic for the jacketing. SWC created and delivered the new cable samples within several weeks of the meeting, which fully met the customer’s needs. The client was impressed with the quality and turnaround time, and has since purchased thousands of feet of this cable every year, and has returned again and again for other cable projects.

A long term client from the mining industry was searching for a new design for a miniature connector required to withstand harsh conditions in a mine. The client has approached many different connector manufacturers in the U.S., but had not yet found a solution that did not involve high up-front costs or long lead times. Within a month of an initial meeting with SWC to discuss their challenges and cable specifications, SWC designed, manufactured, and delivered a sample to the client. With a few discussions and modifications, SWC supplied the client with exactly what they needed. Since then, the client has ordered 200 cables per week.

A client from the oil and gas industry was looking for a specific connector and cable used with pipeline inspection tools. The connector would be subject to high pressures and high temperatures, and the cable needed to be resistant to corrosive and toxic chemicals. SWC met with the client several times to understand the conditions to manufacture a cable that withstood all levels of testing. SWC produced a few prototypes for the customer to approve. Initially, SWC didn’t realize the client was testing with mercury. After discovering this however, a specific protective jacketing material was added, and the next prototype worked perfectly. SWC worked interactivity with the client to successfully design and deliver products that met the client’s specific needs.

SWC was approached by a client from the oil and gas industry to design a cable that would link a complex pipe inspection tool to a control panel. Their current system required multiple cables to deliver power signal, video, pneumatics, plus a strength member between the control system and inspection tool. The numerous cables were difficult to manage and protect while in use, not to mention needing constant repair and maintenance which was costly. SWC designed a single composite cable which combined all elements (electrical, mechanical and pneumatics), with an outer polyurethane jacket for durability. Transition molds were specially designed for both ends to break out the 3 separate cables, which were protected with the same polyurethane jacket. Molds were also designed for the connector ends to ensure the entire assembly was durable. SWC helped the client replace a complex, costly, and operationally inconvenient group of cables with an elegant solution – designing and manufacturing a single composite cable that was durable and easy to manage.

Question about cables? Ask us.

There’s no question we can’t answer about cables and connectors. Ask us and we will get back to you within 1 business day.