Our Specialty Process of Manufacturing & Cable Assembly

What We Can Do

Manufacturing & Assembly

Much of today’s high technology equipment, regardless of industry, requires specialty wires and cables. From pipeline inspection to performance lighting to medical-grade equipment, SWC can customize cable to meet any functionality that your business requires.

Our cable products are designed to withstand extreme conditions such as high/low temperatures, extreme tension, and high compression. We are dedicated to manufacturing the highest quality cable products that your business and community can depend on.

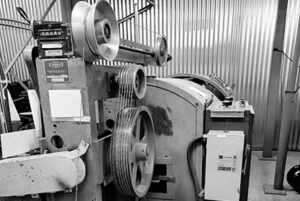

Our team of engineers and technicians are dedicated to innovation in both methodology and technology. We combine innovation with superior materials to manufacture and assemble our cables.

Cable Manufacturing Capabilities

Insulating

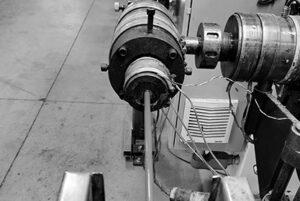

Twisting

Cabling

Shielding / Taping

Braiding

Jacketing

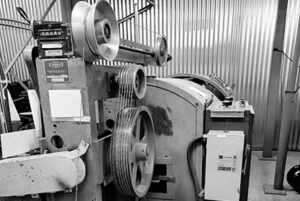

Insulating

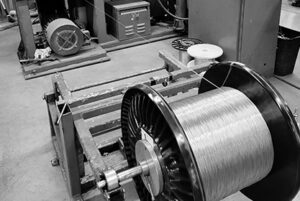

For the highest standard in quality and reliability, SWC is in control of every step, including the very first step – the wire. Our wires are coated with industry-leading plastics for insulation. Every wire we build is rigorously tested with a spark tester to ensure the insolation is perfect. Our specialty capabilities allow us to reel up to 10,000 feet of wire in one spool. The wire gauge can range from anywhere from 3/0 to 28AWG.

Twisting

Cabling

Shielding / Taping

Braiding

Jacketing

25 Years Of Specialty Cable Experience

Manufactured in Alberta, Canada and Texas, SWC has delivered unrivaled customer service. Decade after decade, our loyal customers have depended on us for high quality, innovative, engineered solutions.

Assembly Capabilities

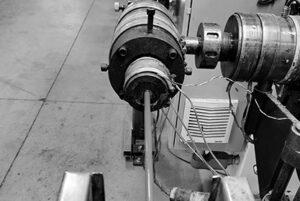

Our in-house assembly capabilities are fully customizable. Every project has different situational and environmental factors that require specialty cable. With design experts, custom machining and molding technology, SWC is primed to support your specialty needs.

Design

Our team of dedicated engineers and technicians use AutoCAD, Mastercam, and SolidWorks to meet any and every assembly, cable and connector specification.

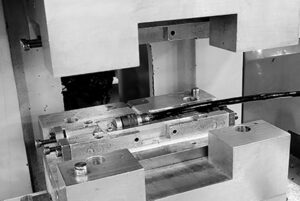

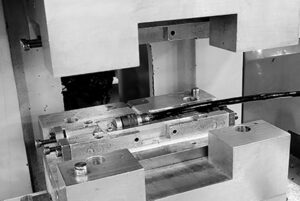

Machining

Termination

Molding

Testing

Delivery

Design

Our team of dedicated engineers and technicians use AutoCAD, Mastercam, and SolidWorks to meet any and every assembly, cable and connector specification.

Machining

Termination

Molding

Testing

Delivery

Superior Quality

Cable Products

Explore a sampling of our standard and specialty cable products.

Cables

Connectors

Services